Equipping Your Service With Customized Welding Examination Services for Every Project

In the realm of organization procedures, the significance of welding evaluations tailored to specific project requirements can not be overstated. Customized inspection intends not only function as an important component of quality control but also play a pivotal function in making sure the structural integrity and safety of the end item. By diving into the nuanced elements of welding evaluation services, companies can unlock a realm of advantages that expand past simple conformity. Whether it be small-scale jobs that demand accuracy or big ventures requiring streamlined performance, the tailored method to welding evaluations stands as a cornerstone for success.

Value of Tailored Welding Evaluations

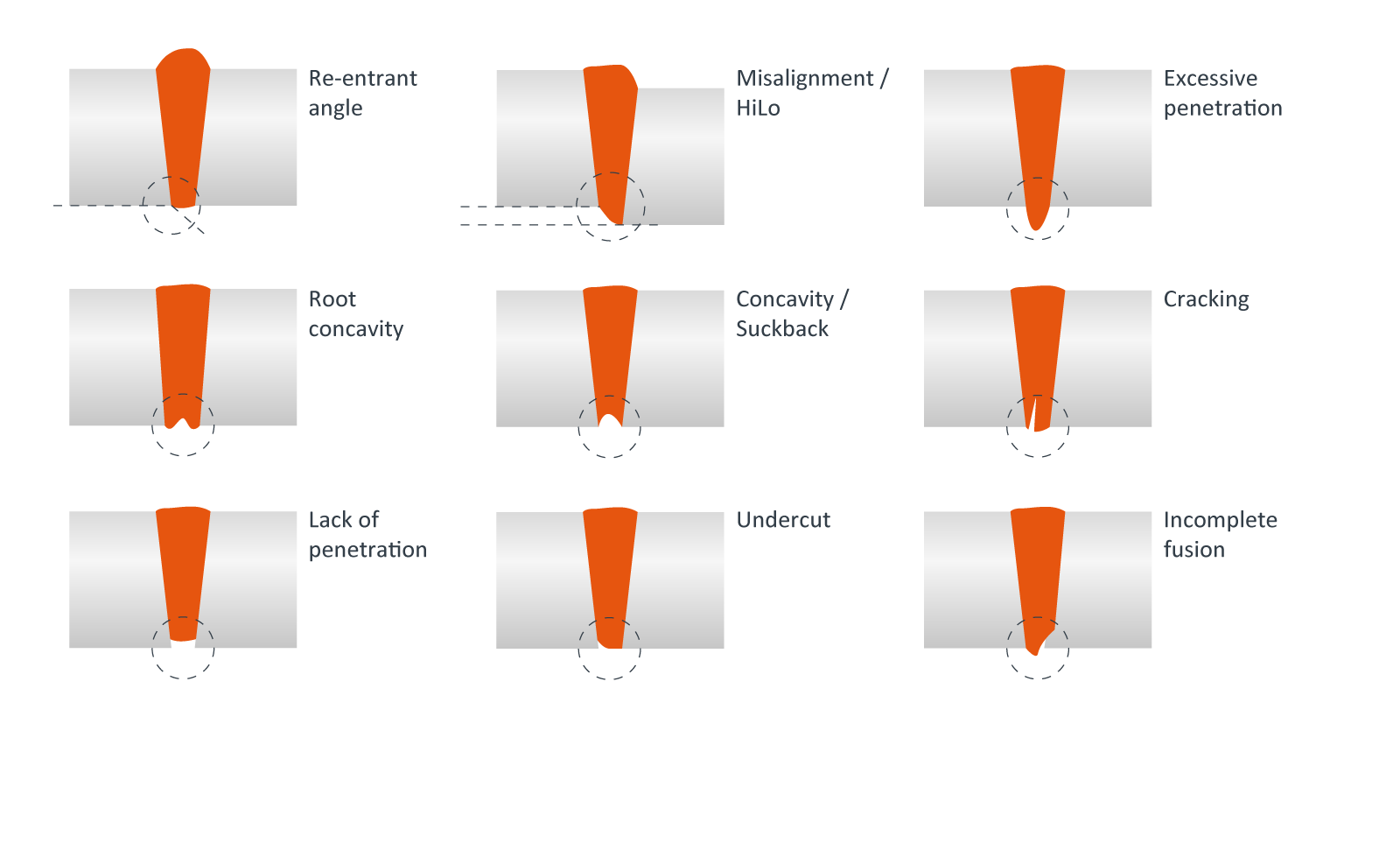

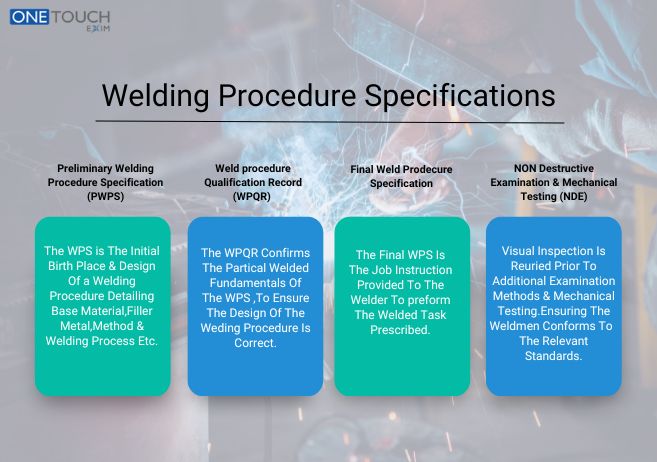

Customized welding evaluations play an essential role in making sure the quality and honesty of welds in different sectors. These specialized evaluations are tailored to meet the details requirements of each task, taking into consideration variables such as the kind of products being welded, the welding method made use of, and the industry requirements that require to be stuck to. By customizing the inspection procedure, potential problems and concerns can be identified and attended to at an early stage, protecting against costly rework or failings down the line.

One trick importance of customized welding inspections is their capability to make certain compliance with sector policies and requirements. Various sectors have differing requirements when it concerns welding high quality, and customized examinations aid businesses satisfy these requirements efficiently. Additionally, customized inspections help enhance general performance and performance by simplifying the inspection process to concentrate on the most crucial areas. This targeted method not only saves time but also enhances the total top quality of the welding job, bring about more secure and extra reliable final product.

Advantages of Personalized Assessment Plans

Personalized inspection plans supply businesses a critical advantage by exactly straightening inspection processes with the one-of-a-kind requirements of each welding project. By tailoring examination plans to fit the certain needs of a project, services can ensure that all vital facets are thoroughly analyzed, consequently lowering the risk of welding problems and making sure conformity with sector standards.

Personalized inspection plans supply businesses a critical advantage by exactly straightening inspection processes with the one-of-a-kind requirements of each welding project. By tailoring examination plans to fit the certain needs of a project, services can ensure that all vital facets are thoroughly analyzed, consequently lowering the risk of welding problems and making sure conformity with sector standards.Additionally, tailored examination strategies help businesses conserve expenses in the lengthy run by protecting against rework and lessening the possibility of project hold-ups. Furthermore, customized assessment plans can boost general task high quality by offering an extra thorough and in-depth assessment of welding procedures, materials, and handiwork.

Tailored Solutions for Small-Scale Projects

For small welding jobs, specialized inspection solutions can be tailored to satisfy the specific demands and constraints of the job scope - Welding Inspection Racine. While bigger tasks commonly have much more standard evaluation processes, small-scale tasks need an extra focused and tailored method due to their one-of-a-kind features

In small-scale tasks, every weld is crucial, and also small defects can have considerable effects. Tailored welding assessment solutions for these projects involve Clicking Here a complete understanding of the project goals, materials made use of, welding strategies, and industry policies. By personalizing the examination plan to suit the scale and intricacy of the task, possible issues can be identified early, causing boosted weld quality and overall job success.

In addition, tailored solutions for small projects can assist enhance sources and decrease prices. By concentrating inspection efforts on areas that matter most for the certain task, unneeded examinations can be avoided, saving both money and time. This targeted technique makes sure that the examination procedure is efficient, effective, and ultimately adds to the successful completion of small-scale welding jobs.

In addition, tailored solutions for small projects can assist enhance sources and decrease prices. By concentrating inspection efforts on areas that matter most for the certain task, unneeded examinations can be avoided, saving both money and time. This targeted technique makes sure that the examination procedure is efficient, effective, and ultimately adds to the successful completion of small-scale welding jobs.Enhancing Effectiveness in Big Jobs

In the world of massive welding jobs, the emphasis moves towards enhancing assessment processes to improve overall efficiency and project success. In such comprehensive endeavors, time is essential, making efficiency an essential consider meeting deadlines and making certain quality. Using innovative assessment strategies, such as automated welding assessment systems and real-time tracking tools, can significantly lower examination times while enhancing accuracy. By incorporating these modern technologies right into the job process, inspectors can promptly recognize locations, discrepancies, or defects requiring rework, enabling prompt restorative actions.

Additionally, developing clear interaction channels and procedures in between evaluation groups, task managers, and welders is necessary for ensuring that evaluations are performed promptly and that any type of concerns are promptly attended to. Applying an organized method to assessment organizing, focusing on critical welds, and assigning sources properly can aid prevent bottlenecks and keep the job on course. Continual training and upskilling of examination personnel also play an important function in improving performance in huge tasks, making certain that assessors are equipped with the most up to date understanding and methods to do their tasks successfully.

Ensuring Conformity and Service Defense

Preserving stringent adherence to welding guidelines and market requirements is critical for protecting company interests and ensuring functional conformity. By prioritizing compliance, businesses can mitigate threats, stay clear of expensive charges, and copyright their reputation within the sector. Welding examination solutions play a vital function in ensuring that all welding refines satisfy the required codes and standards, supplying companies with the guarantee that review their jobs are performed in a certified and risk-free manner.

In addition, conformity with welding guidelines is not practically fulfilling lawful requirements; it is also regarding making certain the safety and security of personnel, the public, and the setting. Non-compliance can cause mishaps, structural failures, and environmental hazards, all of which can have severe effects for a company's bottom line and reputation. By spending in customized welding inspection services, organizations can proactively determine and address conformity concerns before they rise, thereby safeguarding their passions and promoting a society of safety and top quality within the organization.

Conclusion

To conclude, tailored welding inspection solutions play an essential duty in empowering businesses by guaranteeing high quality, compliance, and efficiency in projects of all sizes. Customized inspection plans help businesses meet sector criteria, shield their online reputation, and decrease threats. Whether it's a description small task or a large-scale endeavor, tailored services can boost top quality control and general success. Buying tailored welding examinations is a critical choice for companies wanting to achieve excellence in their welding procedures.

Furthermore, tailored assessments help boost general performance and efficiency by streamlining the assessment process to concentrate on the most crucial locations.Customized examination plans supply companies a strategic advantage by precisely straightening assessment processes with the one-of-a-kind demands of each welding task. By focusing examination efforts on locations that matter most for the particular task, unnecessary evaluations can be stayed clear of, conserving both time and cash. Employing sophisticated inspection methods, such as automated welding assessment systems and real-time monitoring tools, can significantly decrease assessment times while improving accuracy.Moreover, developing clear communication channels and procedures in between examination teams, job supervisors, and welders is crucial for ensuring that evaluations are performed without delay and that any issues are quickly resolved.